lâmina de serra de diamante para corte de concreto armado

sang diamante lâmina de serra força: corte rápido com longa vida útil, economizar energia em energia e pedra. corte rápido com longa vida útil economizar energia em energia e pedra

Marca:

SANGitem número.:

SG-NEW-CONCRETE-111Pagamento:

TT100%,Western Union,Paypal,Money Gram,etcorigem do produto:

Fujian Chinaporto de embarque:

Xiamen or Guangzhou PortTempo de espera:

7~14 days after payment recievedMOQ:

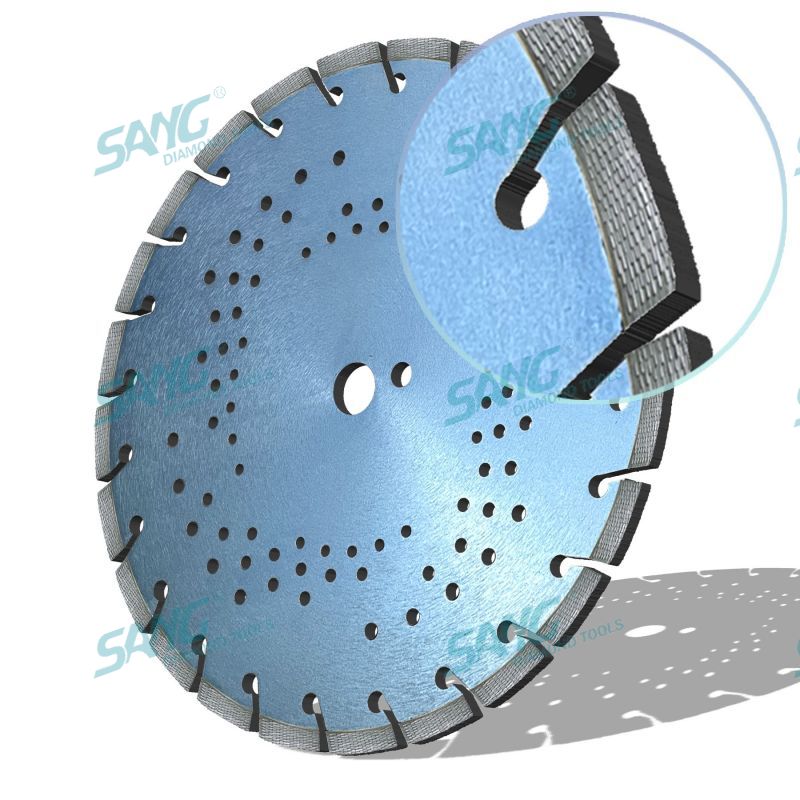

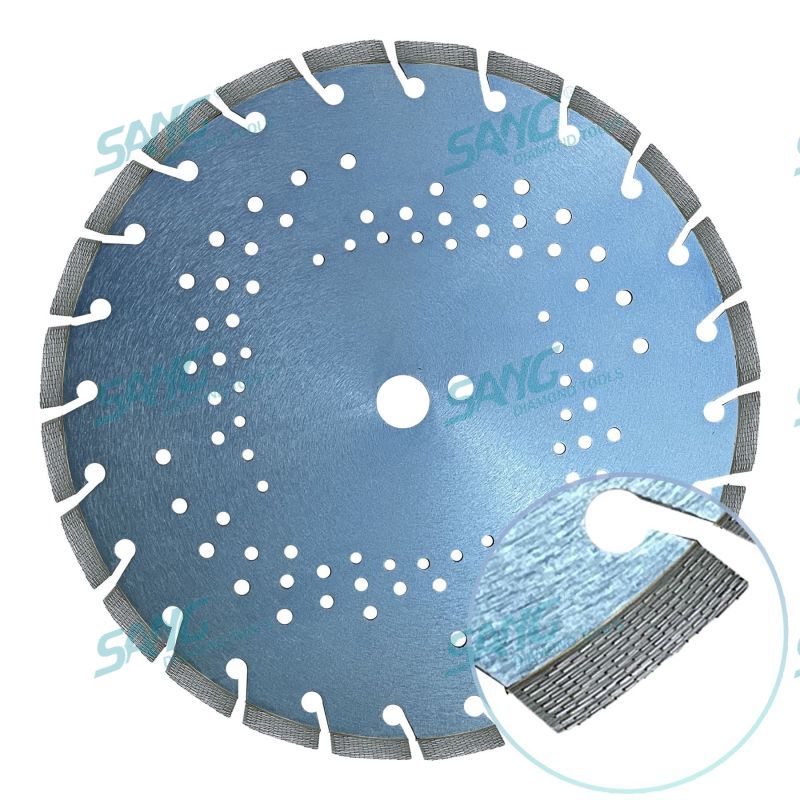

5pcsLâmina de serra de diamante soldada a laser de segmento Arix premium de 16 polegadas para bloco de tijolo de concreto e alvenaria seca ou molhada

Segmentos Arix: Arix é um tipo de tecnologia de segmento de diamante que aumenta a velocidade de corte, o desempenho e a vida útil. Normalmente consiste em múltiplas camadas de diamantes dispostas em um padrão específico, oferecendo maior eficiência de corte.

Soldado a laser: Os segmentos são soldados a laser ao núcleo da lâmina, garantindo uma ligação forte e reduzindo o risco de perda do segmento durante o corte.

Diâmetro de 16 polegadas: A lâmina tem um diâmetro de 16 polegadas, o que é adequado para trabalhos de corte maiores.

Corte úmido ou seco: A lâmina foi projetada para funcionar com métodos de corte úmido e seco. O corte úmido normalmente proporciona melhor resfriamento e supressão de poeira, enquanto o corte a seco oferece conveniência em determinadas situações.

Adequado para vários materiais: Esta lâmina foi projetada especificamente para cortar concreto, tijolos, blocos e alvenaria. Ele foi projetado para suportar os desafios desses materiais e fornecer desempenho de corte eficiente.

Outras especificações disponíveis sob consulta.

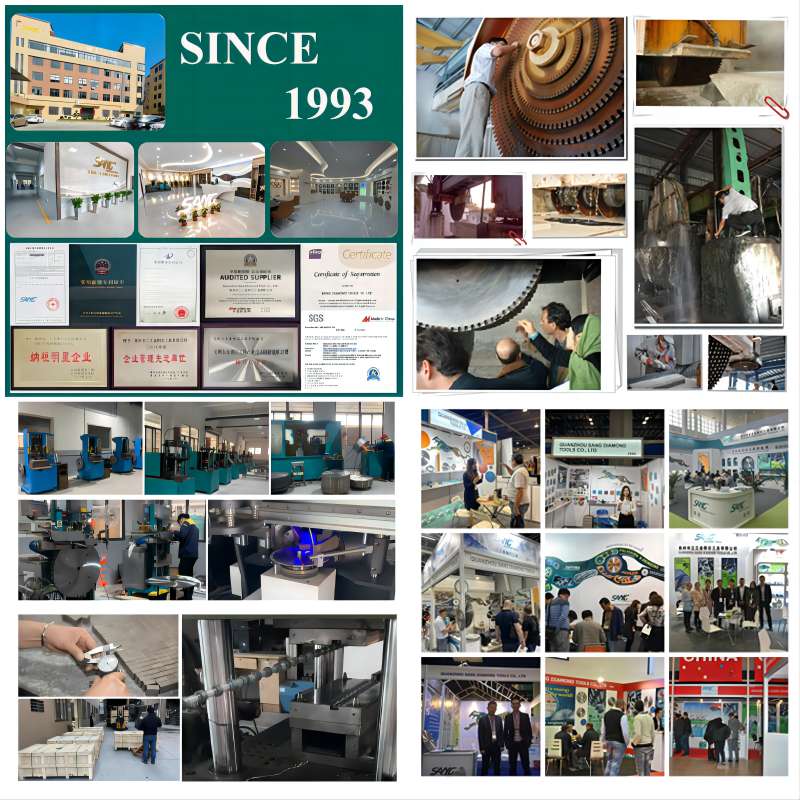

Fornecedor ISO9001 e ouro

Fábrica=Controle de qualidade=Preço competitivo=Tecnologia própria=OEM

Como o processo de soldagem a laser contribui para a resistência e longevidade geral da lâmina?

The laser welding process used in diamond saw blades contributes significantly to their overall strength and longevity. Here's how:

Strong bond: Laser welding creates a strong bond between the diamond segments and the blade's core. This bond is essential because it ensures that the diamond segments remain securely attached to the blade during the cutting process. A strong bond reduces the risk of segment loss, which can lead to inefficient cutting and potential safety hazards.

Heat distribution: Laser welding allows for precise control of the heat distribution during the welding process. This control ensures that the heat is evenly distributed, preventing excessive heat buildup that could potentially damage the diamond segments or the blade's core. By maintaining appropriate temperature levels, the blade's structural integrity is preserved, enhancing its overall strength and longevity.

Enhanced durability: The strong bond achieved through laser welding enhances the blade's durability. It enables the blade to withstand the high stresses and forces encountered during cutting operations. This durability translates into a longer lifespan for the blade, reducing the need for frequent replacements and saving costs in the long run.

Reduced vibration and noise: Laser-welded diamond saw blades often exhibit reduced vibration and noise levels during cutting. The precise and strong bond between the segments and the core helps to minimize vibrations, resulting in smoother cutting operations. Reduced vibration not only improves cutting accuracy but also reduces operator fatigue and enhances user comfort.

Overall, laser welding contributes to the blade's overall strength and longevity by ensuring a strong bond, even heat distribution, enhanced durability, and reduced vibration. These factors combine to provide a reliable and long-lasting saw blade that can withstand the demanding cutting applications in concrete, bricks, blocks, and masonry.

FAQ

1.Are you a manufacturer or trading company?

We are a 31 years manufacturer.

2.How to prove your quality?

We use E6 diamond,Dipea steel wire, passed ISO9001 and SGS,strict quality control and skilled workers.

3.What should I do if the products is not suitable for the market?

Giving us the detailed report first,then we analyze the reason,try to find the solutions.

If it is our problems,we will give you new products.

4.Do you provide free samples?

Small sample is welcomed.But,usually we don't provide free samples.

5.Can you provide OEM/OEM services?

It is ok.

6. Any question about 16 Inch Premium Arix Segment Laser Welded Diamond Saw Blade for Concrete Brick Block and Masonry Dry or Wet, please kindly let me know!Thanks!

Você pode nos contatar de qualquer maneira que seja conveniente para você. estamos disponíveis 24/7 via fax, email ou telefone.